Bulk Material Handling Bag Dump Station Good Powder Dust

Basic Info.

| Model NO. | TLZ |

| Voltage | 220V/380V/400V/415V/440V/480V |

| Transport Package | Standard Export Package |

| Specification | Customized |

| Trademark | Chitong |

| Origin | China |

| HS Code | 8428330000 |

| Production Capacity | 100 Sets/Month |

Product Description

Hurry Enquiry Us!!!TLZ Dust-free Feeding StationProduct DescriptionDust-free feeding station is used for unpacking, delivery, screening and unloading of small bags of materials in pharmaceutical, chemical, food, battery materials and other industries.Dust-free feeding station by the feeding platform, discharge silo, the dust removal system, vibration screen and other components.

| Model | Dust fan(kW) | Vibrating motors(kW) | Dust filter |

| TLZ-1 | 1.1 | 0.08 | 0.4um Coated polyester filter cartridge |

| TLZ-2 | 1.5 | 0.15 | 0.4um Coated polyester filter cartridge |

1) Modular Structure DesignThe modular engineering design guarantees that the machine can be easily installed or configurated with other machines, such as packing machine, conveying equipment or mixer.2)Friendly OperationThe operation is designed to be very simple in order to make sure that workers can acquire the skill rapidly.3)Dust-free Production SpaceDedusting system of bag damping station will always guarantee the clean work space to protect operators and avoid environmental contamination.4)GMP and GMP QualifiedOur bag damping station is strict following the standards of GMP and cGMP and can be used to related plants.

Our Advantages

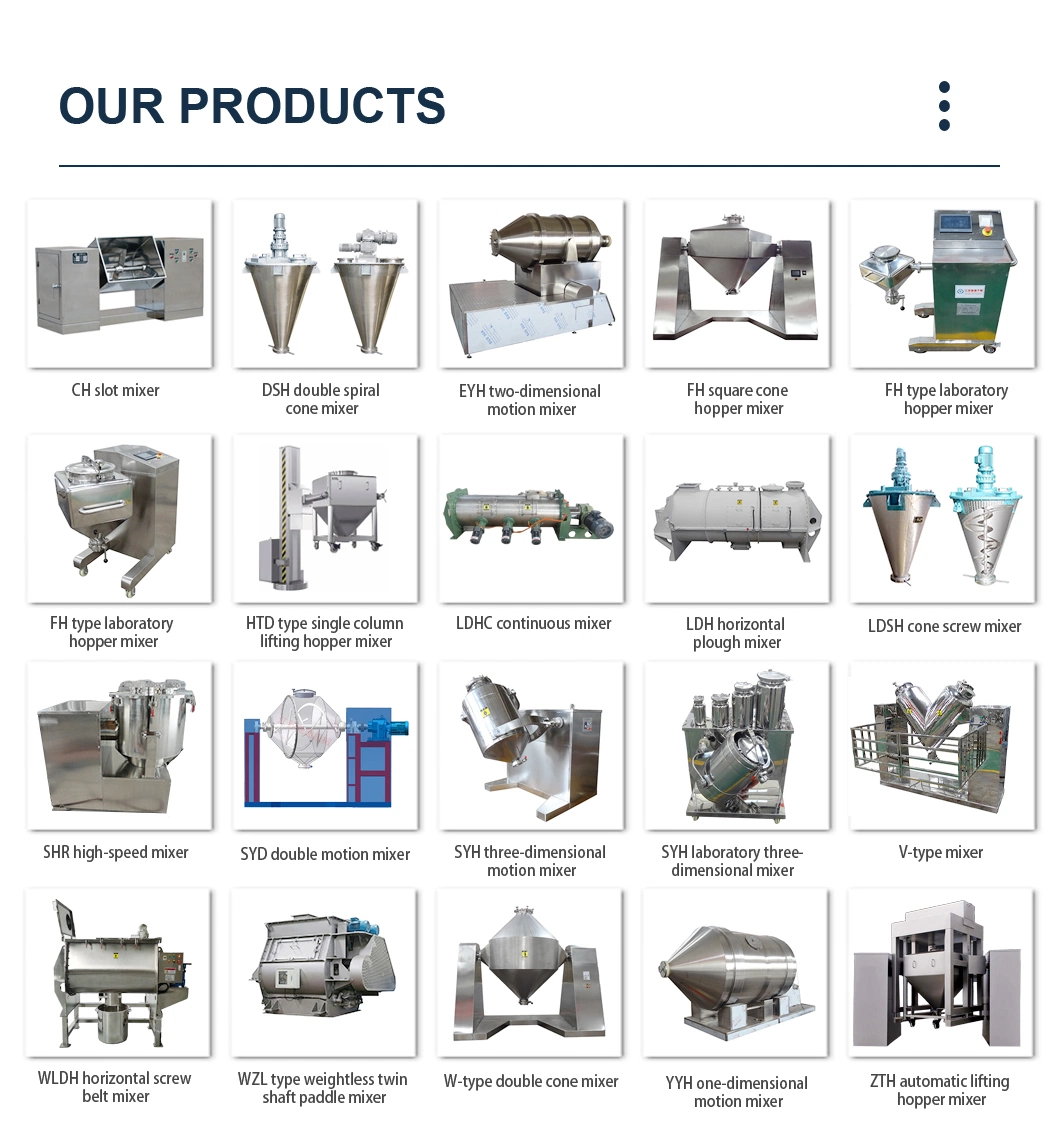

Jiangsu Chitong Machinery Manufacturing Co., Ltd. is a technology manufacturing enterprise integrating R & D, manufacturing and service of dryer, mixer, crusher, granulator, conveyor, vibrating screen and EPC powder equipment engineering. Founded in 2016, Chitong has become a leading powder equipment supplier in China after more than 10 years of development in the original company. Its headquarters are located in Zhenglu Town Industrial Park, Tianning District, Changzhou City, Jiangsu Province.Chi Tong has a R & D team with more than 10 years of development experience and advanced professional production equipment and testing equipment, including R & D center, laboratory, precision lathe, plasma automatic cutting machine, automatic welding machine, automatic grinder, sand blasting room, X-ray weld detection, etc; Since 2016, Chi Tong has carried out extensive technical exchanges and cooperation with world-renowned powder equipment manufacturers, including customized OEM equipment. As a result, Chi Tong's manufacturing technology has been improved by leaps and bounds.Chitong has grown into a dryer, mixer, crusher, granulator, conveyor, vibrating screen and EPC powder project in China. Its annual export volume accounts for about 30% of the total sales. Its products are sold to more than 60 countries and regions in the world, such as Europe, Asia, Africa, North America and South America.

Exhibition photos

1. Are you a manufacturer? Do you have a factory?

We are professional manufacturer with more than 10 years experience in this field.

2. Can the price be reduced for large quantities?Yes, bigger quantity orders are cheaper.3. Do you inspect the finished product? Yes, every production step and finished product will be inspected by QC department before shipment.4. What is the lead time for mass production?Honestly, it depends on the order quantity and the season you place your order.5. Is free shipping available?If you buy a lot of products, the shipping fee is negotiated with the factory.6. Can you send the product to our forwarder in China?Yes, if you have a forwarder in China, we are happy to send the product to them.